Prototype Lee-Enfield 5.56mm calibre

No.4 Cadet Rifle

Please be aware that some specialist imagery may take time to load.

This site is designed for dedicated researchers, and is best viewed on desk or laptop.

See also: British Cadet rifle trials .. - ..The finally selected cadet rifle.. - .. L81A2 Cadet Target Rifle

Also on this page: the wartime activites of the Wilkes London Gunmakers where this rifle was assembled

This rifle was conceived at a time when the military authorities sought designs for a new cadet rifle that would afford a .223-inch calibre training lead-in to the then newly introduced L85A1 (SA80) service rifle of that calibre (5.56mm)

The four-view image below affords close-up inspection.

Hover over or Click image to bring up hi-res file and magnifier

A potted history of the preceding full-bore service rifles may be a useful lead-in to the story of this rifle, very briefly covering the preceding Enfield rifles up to and including those of the 7.62mm NATO calibre, which had succeeded the .303-inch Lee-Metford and Lee-Enfield rifles. These latter personal weapons had done sterling service, themselves being preceded by rebarrelled .577/.450 Martini-Henry rifles - the Martini-Metford rifles - nearly a hundred years earlier in 1889. These conversions were virtually simultaneous to the introduction of the first Lee-Metford rifle. Many of both the Martini and Lee "Metford" rifled arms were subsequently re-barrelled with Enfield rifled barrels, at the same time as Lee bolt-actioned models were being newly manufactured as Lee-Enfield "Long" rifles.

These "Long" rifles were subsequently replaced by the Short Magazine Lee-Enfield (SMLE) variants just after the turn of the Nineteenth Century, themselves succeeded between the two World Wars by the Lee-Enfield Rifle No.4.† The .303 No.4 rifles were finally either converted or newly manufactured around the World in 7.62mm calibre with the arrival of the new NATO ammunition in the mid 1950s, intended mainly for the L1A1 Self Loading Rifle (of the Belgian FAL design). The higher pressure generated by the 7.62mm round required an upgrade to the quality of the steel from which the No.4 action body was made; a factor which had a bearing on the selection of the action of our subject rifle.

The decision made to produce a service rifle in the smaller 5.56mm calibre led to the adoption of the L85A1 SA80 rifle in 1985, for which a need was perceived to provide a suitable training rifle. Up to that point, basic cadet shooting training was largely achieved with small-bore .22 rimfire conversions of the service rifles of the day, that for the No.4 rifle being largely the long-serving Lee-Enfield Rifle No.8. Similar miniature range training utilised .22RF conversion units; adapters such as the L12A1 for the L1A1 SLR, and the later equivalent L41A1 unit for the SA80 rifle.

A full-bore service 7.62mm single-shot Parker-Hale designed target rifle had already been adopted for cadet use, mainly for competition - the L81A1, but something similar was required in the latest 5.56mm calibre.

Large numbers of No.4 rifles were in store in East Africa, and staff at the Enfield Royal Small Arms Factory (R.S.A.F.) had been approached by the Commonwealth Office seeking advice on whether they may have been of use, or otherwise need to be disposed of.

If an effective 5.56mm conversion could be designed for these rifles, they would certainly offer an economical means of providing training or military target rifles in the new calibre. These could have been either single-shot, or magazine-fed had the need arisen and conversion proved straight forward.

Enfield engineers had anyway already been working to design a suitable means to convert the No.4 rifle to 5.56mm Nato. Replacing the barrel was straight forward, but altering the bolt-head to reliably feed and extract the smaller cartridge was not so easy.

The major difficulty with the conversion experienced by Enfield engineers at the R.S.A.F. when modifying the No.4 bolt-head for the rimless 7.62mm Ball cartridge, was the existing extractor arrangement, which required extending, with a proportionately wide slot for the extractor claw in the mouth of the far smaller 5.56mm chamber, causing bulging of the fired case into the groove.

News of this situation reached the ears of John Wilkes at his well-known gunmakers works at 79. Beak Street in London. He heard that staff at Enfield had already even approached some members of the gun trade on the matter. It is worthy of mention that gunmakers and gunsmiths are not one and the same. Gunmakers sign their work, but gunsmiths do not.

At that time, Craig Whitsey was working with John and Tom Wilkes in Beak Street, and advised them that he had an idea for a bolt-head that should solve the problem, but the business was so busy with their existing 'Best" gun trade orders that they did not wish to become involved. However, Craig developed his idea in his own time, acquiring a suitable 5.56mm barrel, machining his recessed bolt-head, and constructing the rifle.

He approach Enfield with his effective design, and also took the barrelled action to a meeting in Whitehall attended by representatives from the various companies putting forward their own designs for the proposed new cadet rifle, including Parker-Hale; but by then the near quarter-of-a-million No.4 rifles in Africa had been otherwise disposed of, and the thinking was evidently of tenders being sought for a completely new product. This was perhaps typical of the modus operandi of big business and inadequately managed Government procurement, as to start completely afresh with a rifle that would require total retooling for manufacture, rather than employ what was available to best advantage by utilising the readily available components of the obsolescent No.4 rifle, would inevitably result in higher cost to the public purse.

Fortunately all was not lost at Beak Street, as word of Craig's effective bolt-head had spread, and he received an initial order for six converted rifles. This was followed by another for 25 conversion sets, which consisted of the bolt-head and an accompanying reground striker. The demand resulted in his making batches of 100 sets to hold in stock.

When building those first six rifles, Craig had made two others "on spec", one of which was the cadet model shown here, which had failed to result in the hoped for military interest. Craig had asked Parker-Hale if they could manufacture barrels for his first rifle conversions, and that company made a mandrel for the purpose. Sadly, after the first four new 5.56mm barrels were produced on their hammer rifling machine, the mandrel broke, and no further units were forthcoming.

The seeming outward simplicity of the action belies the clever thinking that afforded a reliable way to upgrade these near obsolete rifles to the latest calibre.

Only the closest inspection by a Lee-Enfield pundit would reveal the fact that the rifle was no longer what it once was, without inspecting the muzzle for the size of the 'aperture'.

The rifle is fitted with a six-groove 20-inch Douglas barrel.

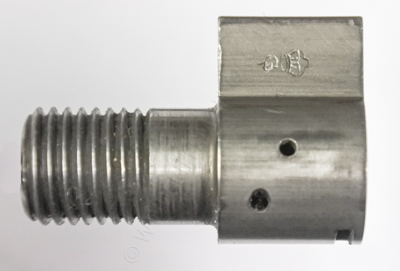

The "in-the-white" breeching washer can be clearly seen in the next image

between the receiver-ring and the barrel-reinforce.

A London proof mark appears on the receiver ring,

and the detail of the calibre is engraved into the barrel.

The nitro proof mark over "NP" is to the left,

the calibre "223 REM" (Remington) is in the centre,

and to the left is "LP" over "11".

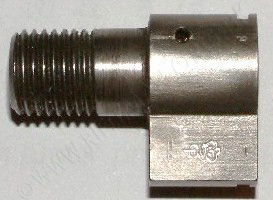

Craig Whitsey worked with John Wilkes for thirty years, and the firm had often liaised with Enfield and Government agencies over that timeyears. During the Second World War (1939-1945)††, it had been involved in design and production of a number of devices employed by S.O.E. (the Special Operations Executive), and the owners and staff were well imbued with an ability for lateral thinking. It was this manner of working that helped Craig develop his totally new design of bolt-head to solve the conversion problem. It has been well worth taking the time to investigate this little-known system, and it is therefore well illustrated on this page. The images show the clever recessed bolt-face with an ingenious extractor arrangement well able to cope with the rimless cartridge, and the particularly effective sprung piston-like ejector within the recess.

The ejection piston can be seen clearly in the left-hand image below.

The extractor is diametrically opposed to it, not quite in view, and is held in place

by a firm spring located behing the staked-in ball-bearing in the lug face.

The image to the right shows the extractor with its chamfered leading face,

which is driven back against the spring pressure as the case-head of the round being chambered enters the bolt-head's recess. Once the case-head is right back against the bolt face in the recess, the extractor drops into the cannular extraction groove of the rimless cartridge, permitting firm extraction of the fired case.

........

........

Next are several views of the unit.

...................

........

........  ........

........

We have made a short video showing two views of the chambering,

extraction and ejection of a 5.56mm drill round.

Click this link or image for the slow-motion clip

The cadet rifle is shown below disassembled.

Hover over or Click image to bring up hi-res file and magnifier

Below: a "3D" Rotate and Zoom image of the subject rifle

permits viewing from any angle.

Drag horizontally to rotate subject - Click to zoom and drag to pan.

Full screen viewing from expansion arrows.

The foreshortened fore-end and upper hand-guard are loosely in the style

of those of the Lee-Enfield L42A1 and L39A1 7.62 mm rifles,

and, of course, the particularly long serving post-war cadet rifle,

the .22RF Rifle No.8, built on the action of the No.5 "Jungle Carbine".

Note that the rifle has been subsequently fitted with

an A.J. Parker

rear-sight windage adapter slide Model 8/53 -

- the latter number being the 1953 date of the design.

This adapter afforded windage adjustment to the No.4 and .22 No.8 rifles

for competition, and was accepted by the Royal Air Forces for such use,

being often seen on the No.8 rifles of the Air Cadets.

Below: a comparison image with the Lee-Enfield L39A1 target rifle at the top,

the 5.56mm converted cadet rifle centre - (of 40.25 inches O/A length),

8lbs. 13ozs. in weight,

and the .22RF No.8 Rifle at the bottom.

Below: an image of the 5.56mm action, with a drill round enetering the chamber,

and the cartridge case-head hidden in the recessed bolt-head.

Below: the magazine with its single-shot loading-platform, which is a lost-wax alloy casting that sits directly on top of the platform of a standard issue .303 magazine.

The components can be seen in the disassembly image earlier on the page.

The bolt-head is marked with the initials that formed Craig Whitsey's original trading name, until Companies House stopped using trade names.

BN18 9AA was the business's post code at the time.

The necessary civilian proof mark is on the lug.

The underside of the bolt-handle still carries its original No.4 marks

The rifle's serial number "8114" is stamped both on the action and the bolt handle.

An inspection mark is on the right-hand side of the bolt-way at the rear of the receiver body.

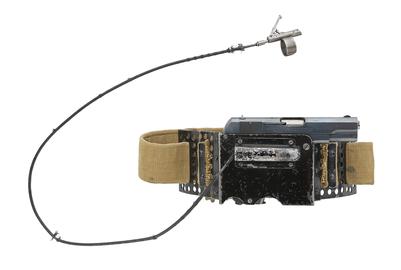

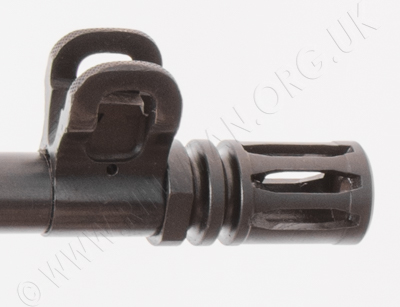

The cadet rifle's Douglas barrel has been thread-cut at the muzzle and fitted with the

early A2 "Birdcage" flash-hider of the 1960's American M16 assault rifle.

However, the unit has been modified with the introduction of a blanking-plate into the frontal aperture. The plate is bored centrally with a hole just safely large enough for the exit of the 5.56mm round, with the intention of adding a limited muzzle-braking capability to the attachment.

The fore-sight block, with its perforated protective wings,

is that from the Lee-Enfield Rifle No.3, more commonly known as the "Pattern '14".

That rifle was itself of a pre-WW1 Enfield design, but manufactured in the U.S.A.

in .303-inch calibre for British use. The Americans also built that rifle in their own service calibre as the "Pattern '17" (1917).

The butt-socket of the Cadet rifle is marked on each side.

...........

...........

The variously described 'crossed sceptres' or 'crossed scimitars' inspection mark

is on the left, showing the date letter "K" in the left quadrant - for 1959.

The letter "B" is in the right quadrant for the Birmingham Proof House,

and the inspector's identification number "3" at the bottom.

The mark on the right-hand side of the socket is not easy to identify.

Both marks are either poorly 'double' or bounce stamped, or have been over-stamped.

It appears to be a representation of a Broad Arrow acceptance stamp with a "g" to its left and a "u" to its right. It is as yet unidentified.

..........

..........

Confirming the date code for 1959, the upper right of the action body casting is stamped, albeit inverted, "D" over "59", indicating an Enfield item of that year.

Being a rifle intended for cadet use, the butt-stock was provided with a Vulcanite rubber recoil-reducing butt-pad, replacing the No.4 rifle's issue metal plate with its butt-trap for oil-bottle and bore-cleaning 'pull-through' weighted cord.

The issue sling swivels for the .303" service rifle have been retained.

______________________

Since using his bolt-head design in the prototype cadet No.4 rifle, Craig Whitsey has sold considerable numbers of them all over the World to those wishing to convert their rifles to 5.56mm calibre. Whilst comparatively small numbers have been sold in the United Kingdom and Europe, low hundreds of them have been exported further afield, to the Antipodes, to both Australia and New Zealand, as well as to the U.S.A., South Africa, and Egypt - where an interest was at one point shown in the cadet rifle itself.

† There were two significant rifles that were adopted between the SMLE No.1 rifle and the No.4 rifle, each being part of the progression from the former rifle to the latter. These were the No.1 Mk. V, followed by last of the No.1 line - the No.1 Mk.VI, which was effectively the prototype and trials rifle for the No.4. For those wondering what may have been the rifles between No.1 and No.4, the No.2 rifle was a .22RF training version of the SMLE, and the No.3 was the Enfield designed WW1 Pattern 1914 rifle that was built in the U.S.A. for British Great War use, and was issued again, twenty years later, to the Home Guard when Great Britain was once more at war with Germany, and threatened with invasion by Nazi forces in 1940.

†† A notable reported wartime incident in the 79, Beak Street works of John Wilkes was during one of Geoffrey De Lisle's visits, initially with his personal .22RF calibre silenced carbine that became the catalyst for his following design for a .45-inch calibre silenced weapon intended for use by the Winston Churchill inspired Commando force.

The "SOE" workshop much later, before clearance.

The carbine was fired down the corridor inside the works through the rear door in the direction of the outside privy. That this was not noticed by nearby neighbours was testimony to the effectiveness of De Lisle's moderator design.

Below: the works shopfront at 79, Beak Street.

The 18th. Century building is now preserved because the type of construction.