The BARNETT "Ten-X" Target Rifles

Nowadays better known for their cross-bow production, the then named J.H.Barnett, Son & Co. Ltd., of Liverpool and Birmingham, once manufactured a very accurate .22 rim-fire target rifle.

This rifle had a most unusual type of action, being a design combination of bolt and under-lever. The system was vaguely similar in operation to that of the equally novel Jurek rifle, except that the bolt locking was effected differently and the bolt was actioned from below rather than from one, or the other, side.

The rifle below is serial numbered 178, and is one of the mid-production models that still carried signs of having been modified from the original rifles with sprung loading platforms; more of which later.

Originally patented in Great Britain in 1947 under Patent No. 17,575, a further patent was filed in the U.S. in 1949.

During the late 1930s designs had already been patented in America for both an under-lever operated bolt-action,

and for a similar light-weighted trigger with minimal pull travel.

Such applications included those by Smith and Jacobson, and are listed in the "References cited" at the end of the patent document replicated below.

This is a searchable flip-page facsimile, may take a few moments to display. N.B. The search magnifier may need to be clicked twice.

Double tap tablet or click ![]() for full page display.

for full page display.

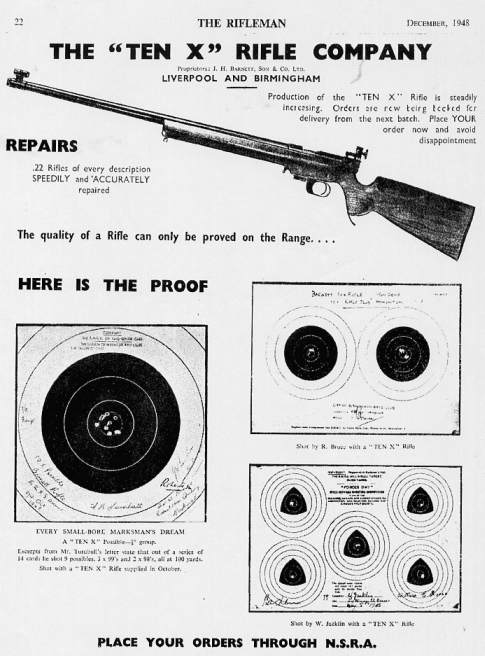

Below: an advertisement for the rifle in "The Rifleman" December 1949

The best description of this rifle can be obtained by reading the article written for "The Rifleman" - the Journal of the N.S.R.A. - (the National Small-bore Rifle Association), in March 1949. The rifle had been introduced between 1947 and 1948 around the time that the N.S.R.A. had been formed out of the Society of Miniature Rifle Clubs late in 1947. The "Ten-X" Barnett was soon updated - in 1949. The N.S.R.A. had started advertising the new product of the "Ten-X Rifle Company" in 1948, soon after production started. Progress was evidently slow because, in December of that year, the advertisement stated that

"Production of the "Ten-X" Rifle is steadily increasing. Orders are now being taken for the next batch. Place YOUR order now and avoid disappointment".

With only around two hundred and fifty rifles at first believed to have been manufactured, either demand outstripped production and customers went elsewhere, or the design was simply overtaken by those of other manufacturers. It would be reasonable to suppose that the introduction of the new BSA Martini International had a considerable bearing on this subject.

The article in " The Rifleman " reads:

"WHEN anything new in equipment appears on the market for British small-bore riflemen, it is an event. When it is in the form of a complete rifle built on original lines, it is indeed something to cause interest. Let us therefore try to give a description of the " Ten X " rifle, - and in doing so, pay tribute to the men, who, knowing the limitations of the market, have laid out a vast amount of capital, as well as thought and man-hours, in trying to produce something new for rifle shooting. Let us remember, too, the enthusiasts who perhaps take a chance in buying these new things, and who are prepared to meet the initial teething troubles for the sake of advancement. How often it is that the man with the long pocket is considered to be taking unfair advantage over the ordinary club shot, but in reality he is paving the way for higher quality for the " rabbit," as happens in all other sports.

Most people now know that the chief of the original ideas in the " Ten X " rifle is the fact that the ACTION is designed to combine the best features of both the Martini underlever and the bolt actions. Various modifications have been, and are in course of being, made to the action. The original model had a bolt circular in its entire length. The loading platform was formed of two spring-loaded plungers which were depressed as the bolt rode over them on its travel forward. Latterly the loading platform has-been replaced by a solid platform and the bolt cut away on the undersides. This simplified loading very much and it is now possible to place the round of ammunition directly on the platform and feed forward with the bolt without shaving or deformation of the bullet. This is effective even if the rifle is canted to quite an angle. The striker travel is very short indeed and the action when adjusted correctly can be described as definitely of the " speed lock " variety. The bolt and striker are made to very fine limits of tolerance and it would hardly be fair to make it a point of criticism that they have to be "run in." Nevertheless, 12 months' steady use does improve the ease and speed of the movement. The description " Miracle " has already been given to the trigger pull of another make of rifle. Perhaps " Magical " would be a fitting word to describe that of the " Ten X." Properly adjusted (and without an instruction sheet or the necessary " know how " the user can have endless fun trying to do it for himself) the rifle may be fired with no apparent travel of, and very little apparent weight on, the trigger; moreover, the weight of pull does not vary and once adjusted correctly will stay put indefinitely. There are three adjustments, one for weight, one for slack up to the point of let off, and the third for take up-of movement after the striker has gone forward. This is simple when one knows how, but it can result in either not cocking or not firing with exasperating results. The makers have been approached on the subject of issuing some simple instruction so that the best results can be obtained quickly and it is understood that this is now being done. The main receiver body is machined from the solid. The bolt and striker are nickel chromed steel, hardened and tempered. All other parts, such as lever, the whole trigger assembly, sear, etc., are machined from the solid drop forging and hardened where necessary, The point of the springs being compression type is a great factor as regards reliability over the leaf-spring type.

The BARRELS are machined from the solid and tubed with Grade " A " hydraulic tubing, correctly heat-treated. The reason for doing this is that where the pressure and wear takes place it is possible to make sure of metal grain flow in the right direction and each batch is tested at Works to withstand bursting strain. This also enables the makers to pre-straighten the tube before and after machining as well as after insertion in the barrel itself (See ParkerRifling) .

Barrels are made in two weights :

(a) Standard 1½ - inches — 1and 1/16 in 3½ - inches, and then a bottle neck taper to ¾ inches for a total length of 28 inches.

(b) Heavy — 1½ inches — 15/16 inches by 28 inches.

Both are tubed, with .216—.2165 dimensions between top of lands. The STOCK is in one piece with a bolt fixing in front of the action and a further bolt passing through the small of the grip, the remainder of the barrel being allowed to float freely.

Some ingenuity is shown in the design of the SIGHTS, The foresight is of tubular variety. The ability to alter the foresight for elevation instead of the backsight gives the obvious advantage of preserving the same pressure of the cheek on the comb of the butt at all distances, a small but important point not usually appreciated by the " Novice". The rearsight is of a more sturdy nature and is now fitted in a dovetail slot on the top of the receiver. Adjustment fore and aft of the eye-piece platform is provided. To those who are accustomed to the British made sight it is as well to give warning that the original models had movement as in the American type of sights, i.e., to raise one " unscrewed " the knob, and to lower one " screwed " it down, but it is understood that present models now follow the established British practice, i.e., right for raise, left for lower. The sights are all machined from the solid and the bugbear of pressings is entirely absent. In GENERAL it can be said that the accuracy of the recent models has been of the best, and this can be attributed partly to the simple design of the action which gives an extraordinary smooth pull on the trigger, and partly to the extreme care taken during the rifling and lapping of the bore. It is perhaps a rifle to which one must get used. Owing to the bolt action being somewhat longer than the Martini block action, the rifle is inclined to feel at first a little muzzle heavy. This feeling, however, is common to all heavy barrelled rifles, and can be overcome by adding lead to the butt to correct the balance, or by an adjustment of the sling tension and the position of the hand stop. Incidentally, if the sling system is correctly adjusted the extra weight of a heavy rifle is hardly noticed, The underlever travels forward on ejection rather farther than the Martini type. This is no disadvantage when the action is " run in " as, when all the parts are nicely lapped, the lever goes forward of its own volition once the movement has got well started. It can be added that the whole rifle is hand finished. It is worth noting that performance is the main attraction with a rifleshot when purchasing a new weapon, and so it should be mentioned that a " Ten X " rifle won its way into the 1948 Dewar Team and also that the tubes used on these rifles are of the same high quality as that which enabled a junior member recently to win the English Section of the National Junior Postal Championships with a fine score of 299 ex 300."

As mentioned in the article, the early models of these rifles were fitted with a spring-loaded single-loading platform that was clipped in place in a "magazine way" ahead of the trigger guard. Some rifles that now have the solid shallow "V" loading platform show evidence of having been built to accommodate the sprung version; the image below shows the two holes, drilled on each side of the receiver, into which the lugs of the unit located.

We have seen the twin plunger loading platform, described in the article, reported as being a magazine. It may be that some rifles were so fitted, but as yet we have no confirmation of this. The only image we have of this to date is, below right, of a rifle sold at Southams auction house.

.......

.......

On such rifles, the slot cut into the stock's woodwork, ahead of the trigger guard,

and through which the spring unit for the platform passed, has usually been filled in;

the insertion of such an 'armourer's repair' is generally obvious,

and can be seen on two of the rotational images on this page.

With the barrelled action removed from the stock, it can be seen that where earlier rifles

had that 'magazine way' slot cut through the base of the receiver body ahead of the trigger group.

Those rifles that were subsequently adapted with the solid platform therefore have its fixing screw offset

to one side of this slot, whereas the fastening for the later models is central.

Hover over image to zoom and pan

We havebeen fortunate enough to acquire this very early example of the rifle, serial no. 11,

and can further describe the configuration of the rather unusual sprung loading platform.

The two separate sprung components can clearly be seen below,

with their piston-like supports, the beneath two outer ones of which are coil springs.

The left-hand image shows the two locking grub screws that locate in two flats

ground into the central pair of 'pistons'. These dictate the amount of vertical movement,

and prevent the pistons popping out of their cylinders.

....

....  ....

....

The short pin, protruding from the rear base of the solid machined 'magazine' block,

indents into a hole at the lower front of the trigger-unit,

preventing the whole unit from dropping out of the rifle,

as the unit is held against the trigger-unit by a long flat spring

fixed with two screws into the base of the barrel's receiver ring.

The 'magazine' slides into a vertical slot machined into the front of the trigger-unit,

as shown in the two images below of the barrelled action removed from its stock.

....

....

The two holes drilled each side of the receiver have been already mentioned,

but it can now be revealed that these are for the rather agricultural-looking bent clips

that hold only the two fixed platform side-plates either side of the removable unit.

Rifle no.11 does not carry any reference to the Ten-X naming,

as it bears neither the logo on the receiver ring, nor the stamping on the muzzle.

We hope to discover in due course the earliest rifles that were so marked.

Observant readers may notice that the above rifle is not fitted with either of the two original types of sights.

It has been modified with different mounting blocks to use the Parker-Hale target sights

that were contemporary standard fitment to the BSA Martini International rifle;

namely the Model PH25 rear-sight and PH1 fore-sight.

For any owner or potential purchaser of a sightless Barnett rifle,

this is a very effective and acceptable alternative arrangement.

We are aware of two Barnett rifles, serial numbers 82 and 99,

that were sold in the December 2020 sale of the Southam's auction house,

each of which were specifically named for Ten-X.

Rifle s/no 82 was fitted with a very smart custom-style stock,

with a nicely chequered, exaggerated horse's-hoof-like pistol-grip, and plain rounded parallel fore-end.

As can be seen, the rifle is still of the early type with the sprung loading platform,

as is the other one sold, s/no.99, also chequered, including the fore-end,

and fortunately still bearing the original 'lumpy' side-mounted rear sight.

Sadly, as the above image shows, number 82 was at the time sightless, a serious and frequent problem when seeking to purchase one of these rifles; but we have acquired the rifle and made the often anyway used modification of fitting it with an early set of Parker-Hale Model 25B sights as used on the BSA Martini International Mk.1. An oddly bent under-lever has been returned to its original elegant shape, and other tidying-up work undertaken.

As can be seen below, the International rear-sight is a neat replacement for the original Barnett sight,

requiring only a new dovetailed action mounting block.

This sight is fitted with an early Parker-Hale eyepiece with adjustable iris,

and with the additional adapter that can hold either coloured filters or a prescription lens - or both.

The pistol-grip's base plate is of horn, rather than the usual matching walnut.

The tube fore-sight from the BSA Martini International is mounted on a block that has two levels, affording an easy switch from 50 to 100 yards ranging without significant elevation adjustment of the rear-sight, which can affect the positioning of the shooter's cheek on the butt comb, with its consequential effect on the eye's sight-line.

The same capability was provided by the original Barnett sloping fore-sight ramp fitted to later production rifles,

permitting the fore-sight to be slid up and down to alter the elevation between 25, 50 and 100 yards.

Below, the "Ten-X" logo is stamped on the barrel reinforce.

The bolt is shown both closed and open;

the latter revealing the two sprung loading platform blocks.

The barrel carries the company name -

" J.H. BARNETT, SON & Co Ltd"

Additionally, the barrel of this early rifle was sleeved by A.G. Parker with their Parkerifling system rather than by the later Phoenix company method.

_________________________________________________________

The next rifle shown below also has a fine custom stock, with an unusual incorporated ammunition block.

It carries the original rather agricultural rear-sight.

Returning to the general description of the rifles,

the image below shows the blanking plate, at the base of the pistol grip,

held by two screws, and concealing the head of the angled rear bedding bolt.

A few rifles built with custom stocks, and with a curved underside to the wrist,

had the heads of the rear bedding bolt recessed but visible.

One such resides in the NRA Museum at Bisley, and is illustrated further down this page.

The mechanical advantage of the Barnett action is considerable. A round not properly fed into the chamber is likely to be crushed if the under lever is brought back swiftly. On initial consideration, the action should theoretically be quite efficient for rapid or timed shooting such as the "Skirmisher" competition. The practice is rather different! The actioning is quite heavy, even though it requires longer lever-travel than is perhaps ideal. This is of no matter whatsoever when shooting deliberate disciplines, but the rifle falls somewhat short of expectations when speed is "of the essence."

The above rifle is serial no. 209.

As at Summer 2006, no complete rifles had been been seen above serial no.250, but since 2015 we now hold rifle no. 305, have had sight of rifles up to serial no.347, and a correspondent from Parker in Colorado recently advised us that he owns a rifle, serial number 417, built up privately from a barrel and action, without sights, which he bought "in the white" around twenty-five years ago. The rifle is reported as being "extremely accurate"; a statement which our experience tells us should be well believed. This particular barrel and action was one of a lot believed purchased by the gunsmith, possibly from auction, and that lot is assumed to be the "tail end" of iron-work production which had lain somewhere unused and unsold from the 1950s.

We have also been passed photographs of a rifle serial numbered 1150, illustrated below.

The serial number is clearly marked.

But the number is particularly high in the general scheme of things.

There is, of course, a possibility that at some point numbers were given an effective start at 1,000

to make the production numbers appear larger than was truly the case; a not unknown ploy.

However, until we see significant levels of such high serial numbering,

we remain reasonably sure that the true production was really only in the low hundreds.

We would be grateful to hear from any custodians of rifles below serial number ten, because it is as yet uncertain at what number the original production serial numbering commenced, although probably No.1, as we have knowledge of rifles s/nos 11 and 20. We are aware that the Imperial War Museum holds rifle s/no. 311 and, as mentioned, we hold s/no. 305; this despite the fact that it had been elsewhere recorded that only about 250 rifles were produced. However, we have also had sight of rifle s/no. 347 shown on this page.

Below , also on rifle s/no.209, is the typical barrel marking used on mid-production rifles.

" J.H. BARNETT SON & Co Ltd "

Left: the specially built rear-sight

Left: the specially built rear-sight

of which the main components

are machined from solid.

Right: the height adjustable

ramped fore-sight.

It should be noted that the Barnett tunnel fore-sight has a fractionally

smaller internal diameter than the equivalent Parker-Hale and BSA models.

The element inserts of the latter two companies will not fit

without filing down the external periphery of their outer ring until it is

barely thick enough to retain structural integrity.

This is very likely the main reason that so many rifles no longer carry their original fore-sights;

and any replacement could not retain the benefit of the ramped dovetail block,

requiring specialist parallel raising blocks.

The original fore-sight permitted sightline height adjustment between the ranges

without requiring the significant adjustment of the rear-sight elevation,

with the disadvantage that one's head/cheek position on the butt is altered.

Such systems have more recently been made available by the accessory market for modern target rifles.

Below - Top left: the early sight,

with its heavy radiussed elevation base screwed to the side of the receiver body.

Top right; the later model (post ca. s/n 180 ?)

with elevation base dovetailed into the top of the receiver body.

The early sight adjustment used the U.S. standard of "Left -Up; Right - Down".

The later model was was changed to match BSA and Parker-Hale's "Right - Up and Left - Down".

........

........

Many owners considered the Barnett sights to be frankly rather clunky and agricultural,

and fitted later sights from Parker-Hale,

particularly on the early rifles, to afford finer and "R-U; L-D" adjusment.

Below left: the Parker-Hale PH.2052 sight has been retro-fitted, as used on the

Winchester Model 52 and Remington Model 37 rifles.

Below right: The Parker-Hale Model 25B rear-sight as fitted to the BSA Martini International rifles.

All of these sights are of nominal 8-clicks to the minute adjustment,

with approximately 0.002" movement per click; roughly ten clicks per turn,

equating to 48 to 50 TPI screw threads.

........

........

The advertisement accompanying the March 1949 article

To to utilise what was probably for them the very best rifling

in the highest quality steel available in the small quantities required,

[the likes of the Birmingham Small Arms Company doubtless servicing only large orders],

the barrels of the Barnett rifles were sleeved by the Phoenix Rifle Repair Co.,

which firm was advertised in Volume 2 of 'The Marksman' journal - July 1950.

The journal was devised and put together by John Knott, of Knott rifles fame.

It was a promising small publication that was sadly exceedingly short-lived.

Many rifles bear the PHOENIX stamp at the muzzle.

Others are marked "TEN-X", and either early rifles or those that may have been

later re-sleeved may be remarked or overstamped "PARKERIFLED - AGP"

The same issue of 'The Marksman' also carried an advertisement for the Ten-X rifles,

but the advertisement bore sad news of the company's potential demise.

It declared "Trade Enquiries Welcomed", but added

" By the liquidators"

" J.H. Barnett Son and Company Ltd."

"(in creditors voluntary liquidation)"

"31, Dale Street, Liverpool"

The standard model then cost £27:10s:0d (£27.50), with the DeLuxe version at £32:10s:0d (£32.50),

weighing 12 lbs and 14 lbs respectively.

A few of the DeLuxe models had their barrels beautifully file-cut for anti-reflection.

Rifle serial number 307 was one such.

The Ten-X motif is shown as usual on the receiver ring,

and the ammunition block swelling on the stock has been later clad with a drilled brass plate,

presumably to prevent and/or disguise wear in the woodwork.

Most of the originally provided stock bulges for this purpose have never been drilled at all.

Below: Barnett rifle serial no. 305, with the heavy barrel, and fitted with the later,

slightly less massive rear-sight dovetailed into the top of the receiver body.

Drag horizontally to rotate rifle - Click to zoom and drag to pan.

Full screen viewing from expansion arrows.

Below: the rifle disassembled.

Click image to bring up hi-res file and magnifier

The disassembled action for closer inspection.

Click image to bring up hi-res file and magnifier

The one-piece efficient twin-extractor bolt, showing the lengthy striker

with (left) the slot into which the Martini-like tumbler's cocking-nose fits.

.........

.........

We attempt to make some sense of the rather unusual means of trigger adjustment commented upon in the 1949 article.

The three adjustment screws are pointed out in the two action images below.

......

......

To aid the explanation, here is our combination of the original 1947 patent sectional drawings,

with a parts key we extracted from the text.

It should be noted that parts 19 to 24 were modified at some time after this patent was filed,

and the screws by which adjustments were made have been replaced by the three grub screws shown in the above images.

Trigger weight is adjusted using the grub screw hidden under the large cheese-head blanking screw at the base of the trigger unit.

The blanking screw has been removed and put to one side in the image below, revealing the adjustment grub screw.

We have compiled two images that show the components as they are

in most production rifles, rather than as shown in the patent drawings.

Below left: the view from the front of the action,

illustrating the positions of the three adjustment screws;

one grub screw on each side, and the weight adjusting set at the bottom.

Below right: the trigger mechanism from the left hand side of the action.

The arrangement is largely as that of the patent drawing,

with the already discussed variance in the adjustment layout.

This design would have afforded a significant saving in the manufacturing costs

of the larger number of components specified by the patent.

Screw A: finely adjusts the let-off; i.e. sear/bent overlap.

Screwing it in too far will prevent release.

Screw B: adjusts trigger travel.

Screw C: adjusts trigger weight.

Apart from the externally accessed adjustment of trigger weight,

short of drilling a small accurately aligned hole through the stock either side of the action,

it is obviously necessary to remove the barrelled action from the stock.

...........  .............

.............

Below left: the spring-loaded thimble can be seen bearing up on the bottom of the front arm of the trigger unit,

and the chamfered end of the grub screw that restricts the forward movement of the trigger,

adjusting the travel, can just be seen bearing on the bevelled upper face of the front arm of the trigger unit.

..........

..........

We hold a facsimile of a letter, initalled by one "B. [J, T or C ?]. H",

part of which relates to the Tenex Rifle Company. It reads ...

"The Tenex Rifle Co. were originally of Longmore Street, Birmingham. Here was the factory works that literally blew down in a night of storm. I arrived next morning for photos of their revolver and rifle set up, only to find the street half-closed by the rubble of the frontage.

The "Ten-X" had a good reputation in its day, the business being taken over around 1950 by W.S. Evans, of Jaycroft Road, Burnham-on-Sea, Somerset.

In reply to a query by some Birmingham firm whose name I cannot now find, and whose letter had been forwarded to W.S. Evans, we wrote "The trigger is capable of lighter setting than any other rifle we know".

The instructions were tedious, but I will forward them if of interest."

That there existed written trigger setting instructions would be of considerable interest to current custodians of these rifles.

If you know of the author, or of the instructions, then do please contact us.

A quite late example of Barnett production has been shown to us, serial numbered 347, and which has been fitted with a BSA Co. barrel.Whether this was as originally manufactured, or is a re-barrelling, is uncertain, but it could well be as it left the factory. The receiver ring bears a far more elaborate Ten-X company motif than that seen on earlier rifles. This would have required a costly piece of tooling for such low volume production.

...

... ...

...

The NRA Museum at Bisley Camp in Surrey also holds an earlier Barnett rifle, serial no. 66 (Ref. 142), donated by the illustrious Andrew St. George Tucker, well known both for his expertise on the range, and for his range of specialist target sights, shooting jackets and other accessories.

The rifle is missing its original contemporary adjustable hooked alloy butt-plate, and has been fitted with BSA International Parker-Hale sights; this has required an unusually high fore-sight mount to be employed. It also carries a Parker-Hale "Quickloader" ammunition block on the RHS.

We have previously mentioned that some rifles with custom stocks

showed the angled rear bedding bolt in recessed counter-bores.

One other unusual aspect is the additional bedding point, consisting of a barrel band pulled down by another bolt about an inch ahead of the barrel's shoulder. Being an International shot, Andrew Tucker may well have retro-fitted this item in an attempt to further improve accuracy.

.  ....

....

The rifle is serial numbered 66 between the barrel band and barrel/receiver shoulder. The rear-sight is a Parker-Hale Model PH25C from a BSA Martini International.

Another rifle with an unusual bedding arrangement is serial numbered 198. It has a stock that has been relieved on both sides of the action, but swells forward on the fore-end, akin to a Remington Model 37, and the butt has been retro fitted with a large cheek-piece.

However, the bedding bolt has been moved into the vertical, and its radiussed cheese-head is let into the underside of the wrist, within the upper section of the channel for the underlever in the pistol-grip.

One other highly unusual Barnett-like rifle, serial numbered 'F.J.B. 123' resides in the NRA Museum collection (Ref. no 148).

It is a target rifle with a Barnett barrel and receiver that has been built up as a left-handed bolt-action.

As with Andrew Tucker's rifle gifted to the Museum, the alloy butt-plate was removed, presumably for use with a newer rifle.

The head of the bolt appears to be similar to the standard rifle, but the left-hand extractor has been modified.

The BSA Sportsman style bolt-handle turning ring can be clearly seen,

as can the upper end of the rear bedding-bolt in the chamfered tail of the receiver body.

Indicative that the trigger group has required significant modification is the adjusting screw within the trigger guard.

The rifle's construction is certainly more modern in nature than the usual Barnetts.

Hex-head socket bedding bolts have been used, and the accessory rail and hand-stop are of more recent style.

However, a bedding bolt has been added only an inch-and-a-half back from the nose of the fore-end,

rendering this anything but a free-floating barrel.

Additionally, the two barrel bedding bolts pull the barrel down using barrel bands,

rather than screwing directly into the barrel, a system used more than fifty years earlier

in such rifles as the 1906 War Office Pattern Miniature Rifle.

The presumed gunsmith is he whose name is engraved on the barrel

"F.J. BARRELL" of Putney, London,

of whom we have thusfar been able to find no reference.

Further on the subject of barrel bands, and explaining the thinking of the time,

we have located a related article published in the March 1949 issue of "The Rifleman".

It is replicated here as a searchable PDF.

In 1952, the Phoenix Rifle Repair Co. were still advertising

in the National Small-bore Rifle Association's journal "The Rifleman".

Their main advertisement is shown here,

and advises potential customers to order via the NSRA.

The NSRA put their own advertising inside the front cover of the journal,

for their sales of rifles, pistols, ammunition and accessories.

At the bottom of the page they offered the available repair services,

including that for the Phoenix company.

It is interesting to compare the various prices for re-sleeving work.

with the Phoenix service, at four pounds, falling between the economy and "All-in" quality for Parkerifling.

Whilst perusing this advertisement, the comparative costs of the various accessories are worth noting.

Offered for £4:8s:0d (£4.40) are aperture rear sights for both the outgoing .22 Lee-Enfield "Smellie" (SMLE) rifle

and for the then relatively newly introduced Lee-Enfield No.8 training rifle.

Foresights are on offer for the B.S.A. small-bore target rifles, and for the Vickers Martini models, at 17/6 (75p).

Nowadays, prices for such classic items on well-known online auction sites can be rather different!

WHAT"S IN A NAME

As a departing, and extremely loosely related subject, we should perhaps mention that the ICI Eley Tenex ammunition that was introduced in 1951, and has performed so well for British target shooters over many decades, has been recorded as having its Tenex name put forward by the well-known and highly successful shot of the times, Arthur Traies, who worked with ICI on its development. One cannot but suppose that his choice may have been influenced by the name of the company about which this page has been the topic.

The 1951 advertisement recording the very first successes of the then brand new ammunition.

See also

Even now a fine target rifle, the Barnett is also an excellent candidate for optic sighted competition, and carries a contemporary telescopic sight particularly well. However, unlike such as the BSA Martini International rifles, many of which were sold fitted with mounting blocks, Barnett rifles so fitted are few and far between, but we have located one early rifle, serial number 11, with suitable mounts, and fitted with the Parker-Hale "Targetscope".

Click or hover over images to magnify

Any suggestion that these rifles were not competitive can be disproved by the performance of rifle s/n 1150 previously mentioned. Shots on 50 metre French targets are shown below, with a fine central group that may usually be expected of rifles decades younger.

For further reference: we copy here the notes on the Imperial War Museum's site, for their rifle s/no. 311. Much of this information has been acquired from our facsimile of the article in the Rifleman journal of March 1949.

The unexplained 'HOEN' reference to the muzzle stamping relates to what must be now an indistinct mark applied by the PHOENIX company, who sleeved the barrels for the Barnett rifles, and operated a barrel relining service similar to that of the Parker companies' "Parkerifling" system. However, it is worthy of note that the IWM rifle's barrel unusually apparently carries both the "PHOENIX" and A.G. Parker "A.G.P. PARKERIFLED" crown stampings.

As each of these marks usually encompasses the entire circumference, we presume that the A.G Parker mark has overstamped the Phoenix one, partly obscuring it, the rifle having been at some time re-sleeved by Parkers.

Physical description

History note

Stamped on top of receiver ring

Stamped on muzzle

Stamped on muzzle

Stamped on left of receiver ring

The Imperial War Museum also holds an example of the Barnett "Trident" crossbow,

tagged as exhibit "11/240".

Finally, a reminder of the Phoenix and related Ten-X companies' repair and sleeving facilities

was added to the article published in the NSRA's Rifleman journal of March 1949.