The Lee-Enfield Rifle No.7 (British)

Please be aware that some specialist imagery may take time to load.

This site is for dedicated researchers and is best viewed on desk or laptop.

A .22" training version of the No.4 Rifle manufactured by the Birmingham Small Arms Co. for the Royal Air Force.

The origin of the .22 No.4 training rifles lay with the immediately post-WW2 plans to develop a rimfire training rifle to represent the No.4 or No.5 .303" calibre centre-fire service rifle. These new rifles were to replace the old .22RF Short Lee-Enfield models(converted S.M.L.E. rifles) that had well provided for this duty since long before the First World War.

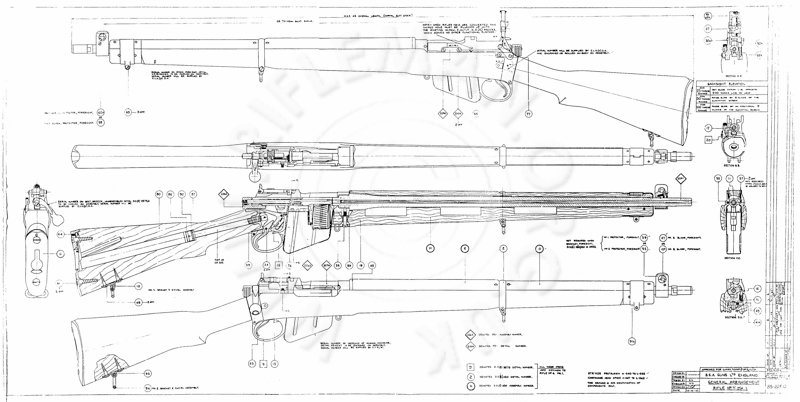

B.S.A. Guns Ltd.'s General Arrangement for the rifle - Drawing No.85-2260 dated 14th. October 1947, is illustrated below.

The Birmingham Small Arms Company took the mantle to develop a suitable design, and produced prototype examples in both the No.4 and No.5 "Jungle Carbine" configurations. At that time, there was a possibility that the No.5 carbine may have been selected as the main service rifle for British forces, the No.4 'long' rifle becoming obsolescent over the ensuing years. This resulted in the production of a hundred or so trials rifles of the No.5 rifle in .22-inch calibre. But a problem with the accuracy of the .303-inch carbine, due to the weakening of the action as a result of the machining away of material to lighten the rifle for paratroop work. This "wandering zero" as it became known, rendered the carbine less suitable for general service, and the No.4 rifle took that place right up to, and even beyond, the introduction of the N.A.T.O. 7.62mm ammunition.

No further work was undertaken on the .22RF carbines, and design time already spent building .22 prototype of the 'long' rifle became the more significant. It was believed by the late Herbie Woodend, curator of the Enfield Pattern Room, that five 'long' .22 rifles were prototyped, but the Pattern Room collection held not one example. The B.S.A. Company's own collection had been split up and sold at auction in the early 1980s, and it was nearly twenty years before one of these rifles surfaced unexpectedly at an arms fair on Bisley Camp.

Stocked in beechwood, and with the serial no. 5, the rifle is prominently marked with its identity.

..........

Another similarly marked rifle appeared a few years later for private sale, but in No.5 carbine form, with the follow on serial no.6. This is represented on the page for the No.5 trials rifle.

Both these rifles were certainly prototypes for the magazine-fed design that eventually led to the configuration of the No.7.

Akin to the No.4 Mk.1/2 .303" service rifle, the trigger was mounted on the action, rather than on the trigger-guard unit set into the fore-end wood as was the case with the No.4 Mk.1.

Solid No.4 barrels were specially manufactured in .22 calibre for the eventual production No.7 riifles, but these did not exist at the time (although B.S.A. had been making these for the conversions of the S.M.L.E.). The barrels for these early prototypes were sleeved in the Parkerifling style.

The bolt-head design was that also used in the .22 No.5 trials rifles, with a rim recess and single traditional extractor lever.

This is shown left below with, centre, the .22 No.6 rifle's bolt-head with the added auxiliary extractor with a traditional fine sharp hook, and right, the No.7 bolt-head showing the final flat spring-steel version with a curved spoon end that purely helped hold the fired case squarely in place on extraction, ready to be struck by the ejector stud on withdrawal.

..

...

For further comparison, see collective detail and images of the bolts for the Rifles Nos. 5, 6, 7 (British), 8 & 9.

The bolt is here illustrated in closed position from beneath up through the magazine-way.

The ejection stud can be seen protruding through the side of the action body.

All the prototype bolts and heads were just polished in the white.

The trials rifles left just the bolt-head unblued, and the No.7 heads were in a Parkerised finish.

Greater detail of the unique magazine arrangement of the prototype and trials models

is given on the page for the No.5 trials rifle.

The pattern for the No.7 rifle having been adopted in 1948, the Birmingham Small Arms Co. manufactured 2,500 of this new .22" training version of the No.4 Rifle for Royal Air Force and R.A.F. Regiment use.

It was fitted with a solid barrel, and a specially produced long bolt head. A standard No.4 magazine had the spring and loading platform removed and a plate riveted into the top with a slot and channel to hold a modified BSA Sportsman five round .22" magazine. This magazine, which in its original utilisation was fitted into the rifle from below, was now inserted from the top by the simple expedient of inverting its locking clip and spring in their box section at the rear of the unit.

This differed from the Canadian manufactured C No.7 in which the magazine-shell was fitted only with a single-loading platform.

Again, for further comparison, see collective detail and images of the bolts for the Rifles Nos. 5, 6, 7 (British), 8 & 9.

The bolt and bolt-head of the C No.7 rifle were, to all intents and purposes,

identical to those of the Royal Navy's N.9 (Parker-Hale No.9) rifle.

Somewhere over 17,000 of the C No.7 rifles were produced at Long Branch between 1944 and 1947.

The left hand side of the receiver of the

British rifle is lightly stamped "No. 7 Mk.I" below which is milled the slot for the ejector

plate. It can be seen below that a spring steel auxiliary extractor is fitted in a slot machined in the left hand side of the bolt head. This has a curved lead (see images below and bolt comparisons) which rides over the cartridge rim when the bolt is closed, and holds the fired case in position against the extractor until the bolt face comes back to the ejector plate whence the case is plucked out of its grip.

The extraction of a fired cartridge case from a a No.7 rifle is illustrated by the following two images.

The auxiliary extractor can just be seen ath the far side of the bolt-head,

which is a few millimetres longer than the prototype unit.

The ejector here having plucked the case by the rim from the bolt-head recess,

and sending it on its way clear of the action.

Note the B.S.A. Sportsman rifle magazine in position in the modified No.4 magazine shell.

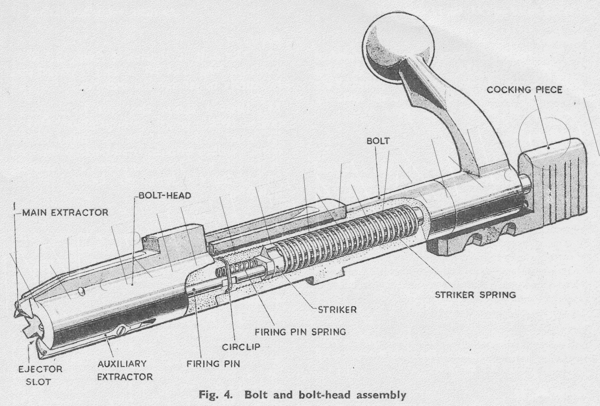

A similar drawing of the action is shown in the No.7 rifle's manual.

With the ejector plate illustrated where it is screwed into the side of the action body.

Note that at this time the sectioned barrel reinforce shows a sleeved barrel.

The manual drawing of the magazine clearly illustrates the B.S.A. Sportsman Five rifle magazine clipped into the rivetted mounting plate of the modified .303 magazine shell.

Owners of Sportsman Five rifles will recognise that the release lever is now at the top of the unit.

In the sporting rifle it is at the bottom, the magazine being inserted into that rifle from beneath.

This is further detailed lower down this page.

A sectioned view of the complete bolt assembly.

The No.7's auxiliary extractor was neither used on the earlier No.5 trials rifle, nor carried forward to the No.8 rifle production. However, in order to reduce the bolt travel of the new No.8 trainer, which was intended to double-up as a target rifle, the bolt head was shortened and the barrel brought back into the receiver a further one and a quarter inches. A further concession to target shooting was that, unlike the No.7 and preceding bolt designs which cocked as the bolt was closed, the No.8 cocked on opening.

On the example of the No.7 Rifle shown above, the left hand side of the butt socket carries the serial number "BS 0341" and the right hand side only the

broad arrow and crown stamp of military acceptance. The magazine carries no marking at all, although some are later stamped with the rifle's serial number.. The rear sight fitted to this rifle uses the standard No.4 leaf graduated for 25,50 and 100 yds, with the additional marking "H" high on the left hand side at the rear. When set at this position, the rifle was said to be "Harmonised". This elevation raised the point of impact by 27" at 25 yards, and was for use with the Landscape training targetry. It has been suggested that the 'harmonisation sight' was not an original standard fitment, however, many of these rifles are so configured and it is by no means certain that either the specification did not change at some point during the production period, or that many rifles were not retro-fitted with this sight.

The barrel was an especially made

solid .22 version with,

unlike the C No.7,

the bayonet lugs still in place.

In 1962 Parker-Hale were advertising surplus No.7 rifles, which they had bought in from the War Office, at £16 for the standard rifle plus £6:10s:0d (£6.50) for the addition of a PH-5D rear-sight. They also offered their own commercial No.9 rifles - equivalent to the Rifle N.9 they had assembled for the Royal Navy - at £15 for the standard example plus a further £5:10s:0d (£5.50) for the PH-5C target rear-sight,.

Even the No.2 Mk.IV S.M.L.E. conversions were still on offer at £10:10s:0d (£10.50).

The 21st. Century prices for such rifles have increased by a factor of around 25, or even more for a pristine original example of the more scarce magazine-fed Royal Air Force issue No.7. The high value has resulted in a number of rifles, of both marks, being built up from a mixture of spares and re-manufactured parts. Caveat Emptor!

It should be noted that, in 1962, the then more up-to-date Enfield No.8 rifle was described as "unobtainable".

Below is a zoomable image of the bolt and bolt-head assemblies.

One other 'magazine' type was used in the No.7 rifle. Its raison d'être has only comparatively recently become fully known to us, but it is a single-shot version carrying a Royal Air Force part number "7B/1061/M" electro-pencilled on its base.

We have discovered its true origins, with the help of staff at the Royal Armouries. A couple of the few units we have come across have a quite roughly machined loading-platform and rather crude trimming of th

e upper periphery of the magazine shell. Two examples we have seen led us to suspect the units to have been on-station unit armourer's modifications using in-house parts made centrally. They certainly did not appear to be of the quality expected from a BSA factory manufactured item. It is believed these magazines were produced to meet a certain training requirement and, perhaps, to cover a deficit of the original units, since the BSA insert magazine can be fairly easily damaged by rough handling or heavy-handed bolt use when a live round or fired case escapes into the 'works' in the magazine-well around the insert.

We have now been advised by a researching staff member at the Royal Armouries that

"correspondence contained in an archived Royal Small Arms Factory (R.S.A.F.) file shows that, in late 1959, the Ministry of Aviation Directorate of Air Armament (D. A. Arm.) asked the R.S.A.F. to produce a design for conversion of the rifle No.7 to single-shot configuration. This occurred at the same time as D.A. Arm. was considering adoption of rifle N.9 for the Royal Navy..

The D.A. Arm. intention was that conversion of the No.7 rifle would be carried out by R.A.F. Maintenance Command units and the R.S.A.F. produced various design options. It is not known how many rifles were involved, but there is no doubt that some were converted and entered service. There is 1962 correspondence on the file indicating that the No.7 rifle auxiliary extractor, which had been removed as a part of the conversion, had to be reinstated by in-Service modification as a result of extraction problems.

The rough finish of the examples encountered tends to confirm that the conversions were carried out at Maintenance Command units. Although the modification drawing list mentions a modification to the body of the rifle, it may be that the original No.7 magazine and the single-loading assembly were interchangeable. This might explain the absence of No.7 rifles in single-;loading configuration."

Our own experimentation certainly indicates no difficulty in the operation of a test rifle with either the 5-round magazine or single-loading 'magazine' in place.

In much the same way as the early Hiscock-Parker magazine made for the .22 "RF Short Mk.II" and converted S.M.L.E. rifles, that preceded the No.7 rifle by several decades, the .22 training versions for magazine-fed rifles proved less reliable than their parental counterparts.

The pivot-pin for the loading platform is held in place by two coutersunk slotted machine screws, just visible at the top edge of the magazine.

A helical spring holds the platform up against the lips of the magazine case.

It rests in counter-bored hole in a block in the base of the magazine.

..........

As already indicated, the front of the platform is supported by the vertical coil spring in the magazine case and, at the rear by the small-diameter transverse pin, which passes through a larger diameter transverse hole in the machined block. On each side, a screw passes through a small hole in the magazine case, near the top, and engages the end of the pin, which is held firmly in position between the sides of the case. This arrangement allows the front and rear of the platform to have a small amount of vertical movement against the vertical spring. It is assumed that the idea was to ensure that the loading platform is pushed upwards to the correct position even if the magazine case sits slightly low when it engages the catch.

Here follow zoomable drawings for the magazine and its components The drawing list is shown first.

We have often been asked if there is anywhere a replacement magazine insert may be found.

Off the shelf the chances are exceedingly slim, but there is an alternative. Please read on .........

For a replacement option for a missing magazine insert, follow the notes below in association with the following image.

Top: the No.7 magazine outer case with rivetted plate to accommodate the insert 5 round .22RF magazine

Lower left: the BSA Sportsman type magazine used for the insert. This is shown, in order to relate to the No. 7 insert, orientated as if it was to be introduced from above into the well of the No.7's modified magazine from the No.4 rifle. In its original usage, the magazine would have been inserted from below the BSA Sportsman rifle, and would have been inverted to the way it is shown in the image. The spring-loaded latching and release lever would have been at the bottom of the magazine below the rifle.

For use in the No.7, the release lever is fitted the other way up, and its fulchrum rivet requires removal, from where it is shown on the left hand image, to where its drilled hole is shown on the centre image. The original rivet hole is removed when the necessary trimming of the case side-plates is undertaken. When the lever and spring are refitted inverted in the case, the release is then at the top of the magazine where it is accessible above the mounting plate in the No.4 magazine shell.

Lower right: An original No.7 insert, partly disassembled, for comparison

PLEASE DO NOT ASK US IF WE HAVE SPARES FOR THESE RIFLES!

The answer is no.

We are aware that a batch of British No.7 rifles was many years ago exported to North America. It appears that the rifles, bolts and magazines were split into separate lots prior to being sold on. This left many rifle owners without either bolts or magazines. We have no idea where they went.

**************************************************************************************************************************

As a result of enquiries and requests made of the editor,here are 16 Images showing detail of the No.7 bolt head;

we have already covered detail of the magazine insert.

Beware the scales, which provide only a rough guide.

Dimensions are not immediately available unless you can find an existing owner who will assist. We do NOT have dimensioned drawings.

Largest JPG file approx. 450 kb

....................

....................

.............................................................

.............................................................

The main extractor pin is too tight to punch out without damage, hopefully enough information for the extractor will be evident when dimensions follow.

................

................

..............

..............

A spring circlip can just be seen in the groove ahead of the threaded rear section

EJECTOR DETAILS - 5 more Images for refurbishers

.................

.................

.

.

See the Enfield Training Rifle Chronology